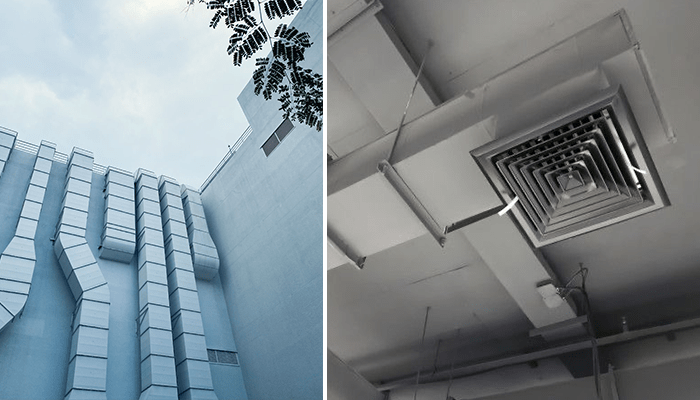

Ventilation Ducting System

Ventilation ducting systems are an integral part of heating, ventilation, and air conditioning (HVAC) systems. They are designed to distribute fresh air, remove stale air, and maintain indoor air quality in residential, commercial, and industrial buildings. These systems consist of a network of ducts that transport air to and from various spaces, ensuring a comfortable and healthy indoor environment.

Key Features and Components of Ventilation Ducting Systems

Ductwork Network

Main Ducts: The primary pathways for air movement within a building. They connect HVAC units to different areas and distribute air evenly.

Branch Ducts: Smaller ducts that extend from the main ducts and deliver air to specific rooms or spaces.

Return Ducts: Ducts that return air back to the HVAC unit for reconditioning and circulation.

Air Handling Units (AHUs)

Function: AHUs are responsible for conditioning and circulating air through the ductwork system. They regulate the temperature, humidity, and filtration of the air.

Components: AHUs typically consist of filters, fans, cooling coils, heating elements, and dampers.

Dampers and Louvers

Dampers: Devices installed within ducts to regulate airflow. They can be manually or automatically controlled to balance airflow and maintain desired temperature levels.

Louvers: Slatted frames used to control airflow and prevent unwanted elements such as rain, debris, or insects from entering the system.

Diffusers, Grilles, and Registers

Diffusers: Installed at the end of supply ducts to distribute air evenly across a room or space. They come in various designs to control airflow direction and volume.

Grilles: Covers for return ducts that allow air to flow back to the HVAC unit while preventing debris from entering the ductwork.

Registers: Similar to grilles, but with adjustable dampers to control the amount of air that enters a room.

Insulation

Thermal Insulation: Applied to ducts to prevent heat loss or gain, ensuring energy efficiency and maintaining the desired temperature.

Acoustic Insulation: Used to minimize noise generated by airflow and mechanical components within the duct system.

Flexible Ducts

Purpose: Flexible ducts are used to connect rigid ducts to diffusers, registers, or other system components in tight or complex spaces. They are easier to install and can be bent around obstacles.

Material: Made from materials such as plastic, aluminum, or fiberglass, flexible ducts are lightweight and provide versatility in duct design.

Types of Ventilation Ducting Systems

Sheet Metal Ducts

Material: Made from galvanized steel or aluminum, sheet metal ducts are durable, resistant to moisture, and provide low friction loss for efficient airflow.

Application: Commonly used in commercial and industrial settings where strong and long-lasting ducts are required.

Flexible Ducts

Material: Made from flexible plastic over a metal wire coil, they are lightweight, easy to install, and ideal for tight spaces.

Application: Suitable for short runs and connections between rigid ductwork and diffusers.

Fiberglass Ducts

Material: Made from fiberglass panels with an interior coating, these ducts offer excellent thermal and acoustic insulation.

Application: Often used in office buildings and theaters where noise control is a priority.

Fabric Ducts

Material: Made from permeable or non-permeable fabric materials, these ducts are lightweight, easy to install, and provide uniform air distribution.

Application: Ideal for applications like gymnasiums, pools, and factories where condensation and corrosion resistance are essential.

Polyurethane and Phenolic Ducts

Material: Made from polyurethane or phenolic foam panels, these ducts are lightweight and provide good thermal insulation.

Application: Used in commercial settings where lightweight and energy-efficient ducts are needed.

Design Considerations for Ventilation Ducting Systems

Airflow and Sizing

Proper Sizing: Ensuring ducts are sized correctly is essential for maintaining optimal airflow, reducing energy consumption, and avoiding issues like pressure drops, noise, or hot and cold spots.

Balanced Airflow: Balanced airflow ensures the supply and return air is equal, preventing negative or positive pressure imbalances that can impact comfort and energy efficiency.

Material Selection

Durability and Corrosion Resistance: The choice of duct material depends on environmental conditions and specific application needs. For instance, galvanized steel and aluminum are used in environments where durability is a priority.

Thermal and Acoustic Insulation: Choosing the right insulation materials can improve energy efficiency and reduce noise levels.

Installation and Maintenance

Accessibility for Maintenance: Ducts should be installed in a way that allows for easy access for cleaning, inspection, and maintenance.

Sealing and Insulation: Proper sealing of ducts prevents air leaks, ensuring efficient airflow and energy savings. Insulating ducts prevents heat gain or loss, maintaining desired temperatures.

Energy Efficiency

Minimizing Pressure Drops: Proper duct design minimizes pressure drops, reducing the workload on the HVAC system and improving energy efficiency.

High-Efficiency Fans and Filters: Using energy-efficient fans and high-quality filters reduces energy consumption and improves indoor air quality.

Applications of Ventilation Ducting Systems

Residential Buildings

Single-Family Homes and Apartments: Ventilation ducting systems ensure proper air circulation, maintain indoor air quality, and provide heating and cooling.

Commercial Buildings

Offices, Hotels, and Retail Spaces: In commercial settings, ventilation systems provide comfort and maintain air quality for employees, customers, and guests.

Industrial Facilities

Factories, Warehouses, and Workshops: In industrial environments, ventilation systems are crucial for removing dust, fumes, and airborne contaminants, ensuring a safe working environment.

Healthcare Facilities

Hospitals, Clinics, and Laboratories: Ventilation systems in healthcare facilities are designed to control the spread of airborne pathogens, ensuring a sterile and safe environment.

Educational Institutions

Schools, Colleges, and Universities: Ventilation systems in educational settings ensure proper airflow and maintain a comfortable and healthy learning environment.